What precautions should be taken during the installation and use of low-frequency pin-type transformers?

2026-01-06

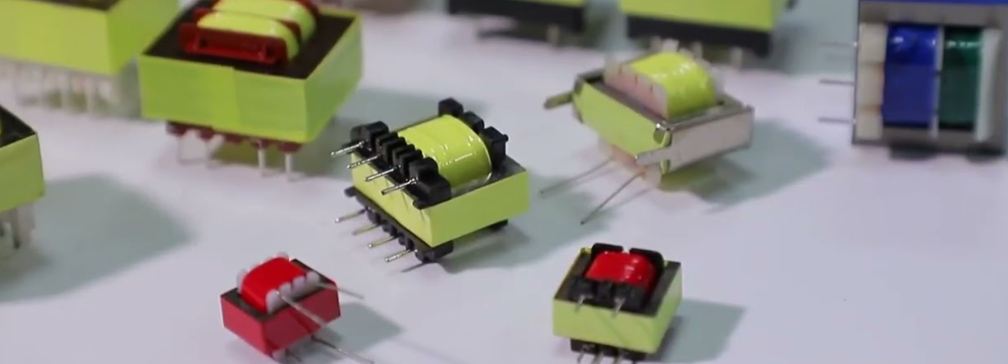

Low-frequency pin-type transformers are widely used in power supply equipment, industrial control, power electronics, household appliances, and instrumentation. They are primarily used for voltage conversion, electrical isolation, and stable power supply. Because low-frequency pin-type transformers typically operate in 50Hz or 60Hz power environments, they have relatively high power, size, and weight. Therefore, special attention must be paid to various details during installation and use to ensure safe, stable, and long-term operation of the equipment.

1. Precautions Before Installation

Before installing a low-frequency pin-type transformer, confirm that the transformer's technical parameters match the operating environment and equipment requirements. Parameters such as rated input voltage, output voltage, rated power, and operating frequency must be consistent with the actual circuit design. Improper selection can easily lead to transformer overload, severe overheating, or even damage.

Secondly, check the appearance of the low-frequency pin-type transformer to ensure it is intact, the pins are neat and secure, and there are no deformations, looseness, or damage to the insulation layer. If any abnormalities are found, avoid direct installation and use. Furthermore, confirm that the transformer's insulation class and voltage withstand capability meet electrical safety standards, which is especially important in industrial or high-demand applications.

2. Key Points for Correct Installation of Low-Frequency Pin Type Transformers

During installation, the fixing method is crucial. Low-frequency pin-type transformers are usually installed by soldering or plugging the pins onto a PCB board. Due to their relatively large weight, it is recommended to reserve sufficient support area in the PCB design, and if necessary, use screws, brackets, or adhesive for fixing to prevent solder joint fatigue caused by long-term vibration or impact.

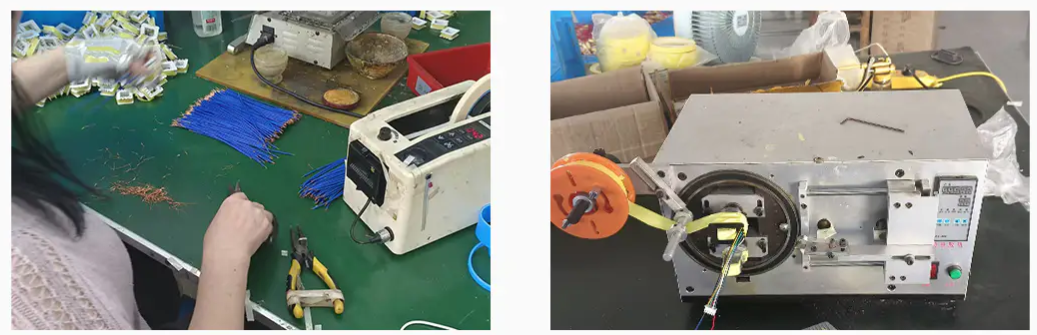

When soldering, ensure that the pins are in full contact with the solder pads, and the solder joints are full and secure, avoiding cold solder joints or poor connections. The soldering temperature and time should be controlled appropriately to prevent damage to the transformer's internal structure or insulation materials due to overheating. At the same time, sufficient electrical clearance should be maintained between the pins to avoid short circuits or creepage risks due to insufficient spacing.

The choice of installation location is also very important. Low-frequency pin-type transformers generate a certain amount of heat during operation, so they should be kept away from temperature-sensitive components. A reasonable layout not only helps with heat dissipation but also reduces electromagnetic interference to surrounding circuits.

3. Precautions when using low-frequency pin-type transformers

In practical use, load matching is crucial for ensuring the stable operation of low-frequency pin-type transformers. Avoid prolonged overload operation, as this can lead to core overheating, coil insulation aging, and a shortened lifespan. It is recommended to reserve a certain power margin to cope with instantaneous current fluctuations or load changes.

The stability of the power supply voltage is equally important. Input voltage that is too high or too low will affect the transformer's output performance and safety. Prolonged operation under abnormal voltage conditions may lead to unstable output voltage or even damage to downstream circuits.

During operation, pay attention to the temperature rise of the transformer. If abnormal heating, unusual noises, or a burning smell are detected, immediately disconnect the power and inspect the transformer. These phenomena are often signs of overload, short circuit, or internal failure, and continued use poses a significant safety hazard.

4. Electromagnetic Interference and Safety Protection

Low-frequency pin-type transformers generate a certain electromagnetic field during operation, which may affect surrounding sensitive circuits. To reduce interference, reasonable wiring arrangements should be used in the design, and shielding measures or filtering circuits should be added if necessary. Good grounding design also helps improve the electrical safety and anti-interference capabilities of the system.

In applications involving human-machine contact or high safety requirements, electrical isolation performance should be given special attention. Ensure that the primary and secondary windings of the low-frequency pin-type transformer have sufficient insulation distance and voltage withstand capability to avoid leakage risks.

5. Daily Maintenance and Inspection Suggestions

Although low-frequency pin-type transformers have a relatively stable structure, regular inspection is still very necessary. It is recommended to regularly check whether the solder joints are firm, whether the pins are oxidized, and whether the insulation material is aging. If any abnormalities are found, they should be replaced or repaired promptly.

At the same time, keep the inside of the equipment clean, avoiding long-term accumulation of dust and oil on the transformer surface. This helps with heat dissipation and reduces the failure rate. When used in high-temperature or high-humidity environments, the inspection frequency should be increased to ensure the long-term reliable operation of the transformer.

The installation and use of low-frequency pin-type transformers are not complicated, but they require attention to detail. From selection and installation to daily use and maintenance, every aspect directly affects its performance and lifespan. Only by strictly adhering to standard operating procedures can low-frequency needle-type transformers reliably perform voltage conversion and electrical isolation, providing safe and reliable support for the entire power supply system.

English

English 中文简体

中文简体