Is the moisture resistance of low-frequency encapsulated transformers good?

2026-01-27

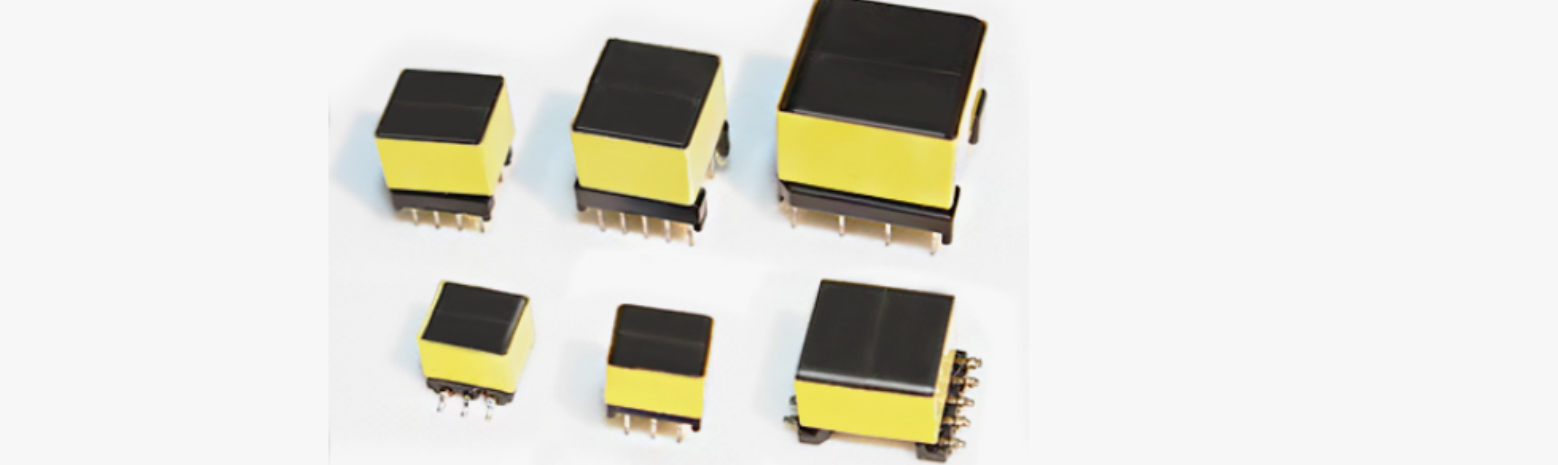

In power systems and various industrial equipment, environmental factors often directly affect the stability and service life of transformers. Among these factors, humid environments are one of the main causes of electrical equipment failure. Due to their special structural form, low-frequency encapsulated transformers are widely used in applications requiring high levels of moisture resistance and protection. So, how good is the moisture resistance of low-frequency encapsulated transformers?

1. What is a low-frequency encapsulated transformer?

Low-frequency encapsulated transformers typically operate in 50Hz or 60Hz AC environments. In addition to performing voltage conversion and electrical isolation, the coils and core are completely encased in potting material through an encapsulation process. Common potting materials include epoxy resin and polyurethane. These materials, after curing, form a dense protective layer, effectively isolating the internal structure of the transformer from the external environment.

It is this overall encapsulation structure that gives low-frequency encapsulated transformers significant advantages in terms of moisture resistance, dust resistance, and pollution resistance.

2. The principle of moisture resistance in low-frequency encapsulated transformers

The excellent moisture resistance of low-frequency encapsulated transformers mainly stems from the following aspects:

The potting material itself has a low water absorption rate. The cured resin effectively blocks moisture penetration, preventing moisture from directly contacting the coils and core, thus avoiding insulation degradation and changes in electrical performance caused by dampness.

The encapsulation process reduces air gaps. Traditional unencapsulated transformers have certain gaps inside, where humid air can easily accumulate. The encapsulated structure fills these gaps, making it difficult for moisture to enter the internal structure.

The overall encapsulation improves insulation reliability. The potting material not only provides moisture resistance but also enhances the insulation strength between the coils and between the coils and the core, maintaining stable electrical performance even in humid environments.

3. The importance of moisture resistance to equipment operation

In high-humidity environments, ordinary transformers are prone to problems such as decreased insulation resistance, increased leakage risk, and partial discharge, which can even lead to short circuits or damage in severe cases. Low-frequency encapsulated transformers can significantly reduce these risks by effectively isolating moisture, thus ensuring the long-term stable operation of the equipment.

For power supply systems that require continuous operation over extended periods, moisture resistance is not only crucial for the reliability of individual transformers but also directly impacts the safety and maintenance costs of the entire system. Using low-frequency encapsulated transformers can reduce failures caused by environmental humidity and improve overall system stability.

4. Moisture Resistance Advantages in Typical Application Scenarios

Low-frequency encapsulated transformers are commonly found in outdoor equipment, underground facilities, industrial sites, and electrical systems in high-humidity areas. For example, in industrial control cabinets, automation equipment, power modules, and lighting systems, environmental humidity is often difficult to control completely, and encapsulated transformers provide more reliable protection.

Furthermore, in coastal areas or humid and hot climates, where there is more moisture and corrosive elements in the air, the sealed structure of low-frequency encapsulated transformers helps extend their lifespan and reduce performance degradation caused by environmental factors.

5. Precautions When Using Low-Frequency Encapsulated Transformers

Although low-frequency encapsulated transformers have excellent moisture resistance, proper selection and installation are still necessary in practical applications. The appropriate encapsulation material and protection level should be selected based on the operating environment, and sufficient heat dissipation conditions should be ensured for the transformer. Due to the relatively enclosed encapsulation structure, heat dissipation mainly relies on the casing and surrounding environment; adequate installation space helps prevent performance degradation due to excessive temperature rise.

In electrical design, prolonged overload operation should be avoided to prevent excessively high internal temperatures from adversely affecting the encapsulation material.

Low-frequency encapsulated transformers demonstrate excellent moisture resistance. Through the overall protection of the encapsulation material and structural optimization, they can effectively isolate moisture, improve insulation reliability, and reduce the impact of humid environments on electrical performance. For power supply systems that need to operate stably in complex or high-humidity environments, low-frequency encapsulated transformers are a reliable and practical choice, playing an important role in ensuring equipment safety and extending service life.

English

English 中文简体

中文简体